ROCHEM ® system design is based on 30 years of experience of installation of more than 3000 units on ships of different kinds and sizes and more than 700 units on naval ships, such as frigates, corvettes, helicopter carriers, mine hunters, patrol boats, submarines, etc.

| Designed and constructed for continuous operation to desalt and purify: – Sea Water – Brackish Water – City Water – Industrial Waste Water |

LOW-Energy–and without chemical pre-treatment

|

|

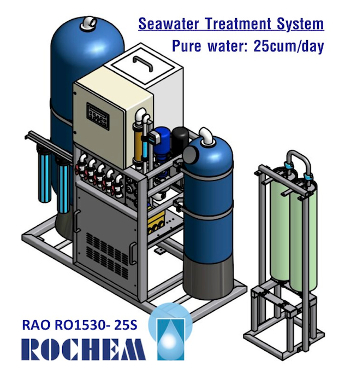

Unit type: RAO ROCHEM RO1530‐25S Capacity: approx. 25 m3 / day potable water |

|

| Number of ROCHEM® TS-Modules | 2 | |

| Operation pressure | 60 – 70 bar | |

| Connected power | 10-13 Kw – 440v / 60 Hz / 3 phase | |

| Weight | DRY 1.470Kg (in operation 1.720Kg) | |

| Dimensions (L x W x H) | 2.400 x 800 x 2.185 (mm) | |

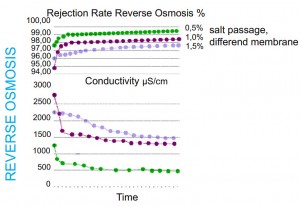

| Raw Water Salinity, design | Sea Water, open sea: 36.000 ppm TDS; pH 7,8 | |

| Pure water output | 340-500ppm TDS; pH 6,3 – 6,5 | |

RAO RO‐Plant designed for the special requirements on ships. The RAO RO‐Plants can produce naturally pure potable water with app. 500 mg/l of remaining minerals at a seawater temperature of 25°C. The quality of the produced water will be in accordance to the latest requirements of the WHO.

|

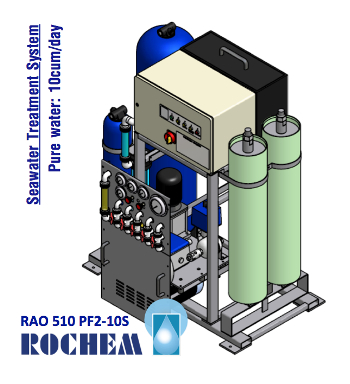

Unit type: RAO ROCHEM 510 PF2-10S Capacity: approx. 10 m3 / day potable water |

|

|

| Number of ROCHEM® PF-Modules | 2 | |

| Operation pressure | 60 – 70 bar | |

| Connected power | 5 kW – 400V / 50Hz (440V / 60Hz) / 3 phase | |

| Weight | DRY 670Kg | |

| Dimensions (L x W x H) | 1.190 x 705 x 1.500 (mm) | |

| Raw Water Salinity, design | Normal sea water: 36.000ppm TDS; pH 7,8 | |

| Pure water output | Between 340 & max. 500ppm TDS; pH 6,3 – 6,5 | |

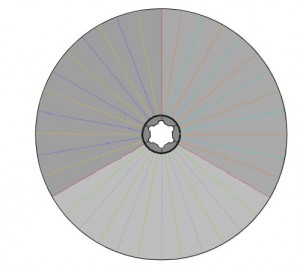

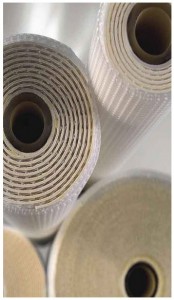

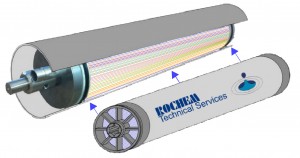

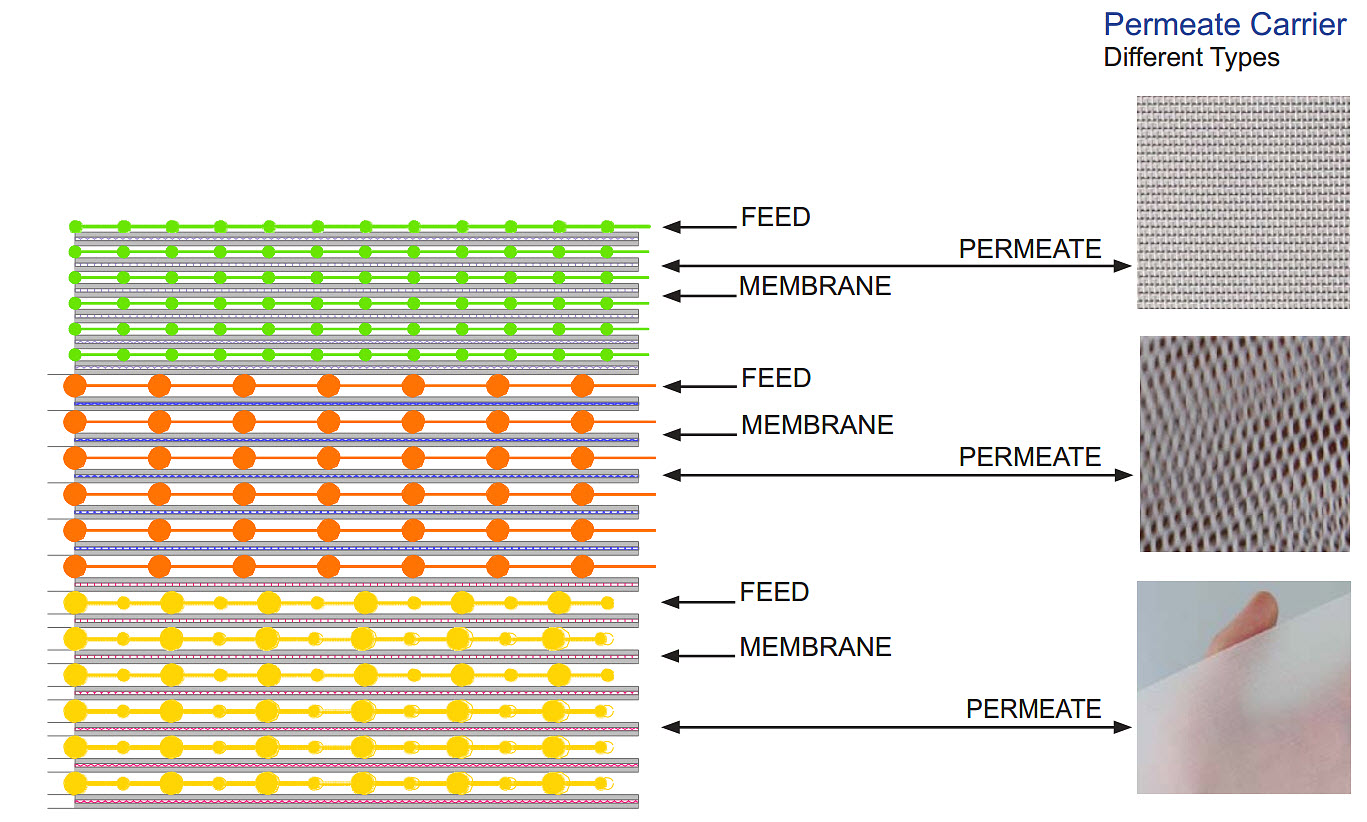

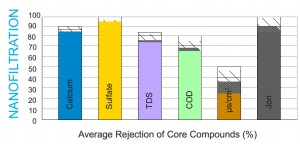

The RAO ROCHEM Fresh Water Generators use the reverse osmosis principle. In this cross flow mode of filtration, a percentage of the feed water permeates through the reverse osmosis membranes, to produce water that is free from suspended solids, bacteria and viruses. This process is sensitive to the temperature and salinity of the feed water.

|

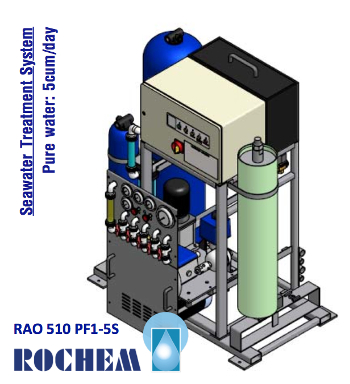

Unit type: RAO ROCHEM RO510-PF1-5S Capacity: approx. 5 m3 / day potable water | |

| Number of ROCHEM® PF-Modules | 1 | |

| Operation pressure | 60 – 70 bar | |

| Connected power | 3 kW – 400V / 50Hz (440V / 60Hz) / 3 phase | |

| Weight | DRY 680Kg (in operation 780Kg) | |

| Dimensions (L x W x H) | 1.190 x 705 x 1.500 (mm) | |

| Raw Water Salinity, design | Sea Water, open sea: 36.000 ppm TDS; pH 7,8 | |

| Pure water output | 340 – 500 ppm TDS; pH 6,3 – 6,5 | |

|

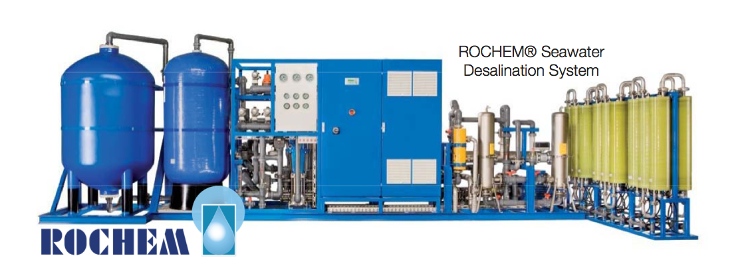

With Rochem technology, seawater treatment plants are designed with capacity of 2m3/day to 100m3/day for kinds of ships. Plants designed with 600m3/day to 100.000m3/day for residential areas, islands. |

COMPREHENSIVE WATER MANAGEMENT Seawater Desalination and waste water treatment on ships and offshore platforms RAO serves the needs of the ship´s crews and offshore platform´s operators for high-quality drinking water and for environmental-friendly waste water treatment. |

|

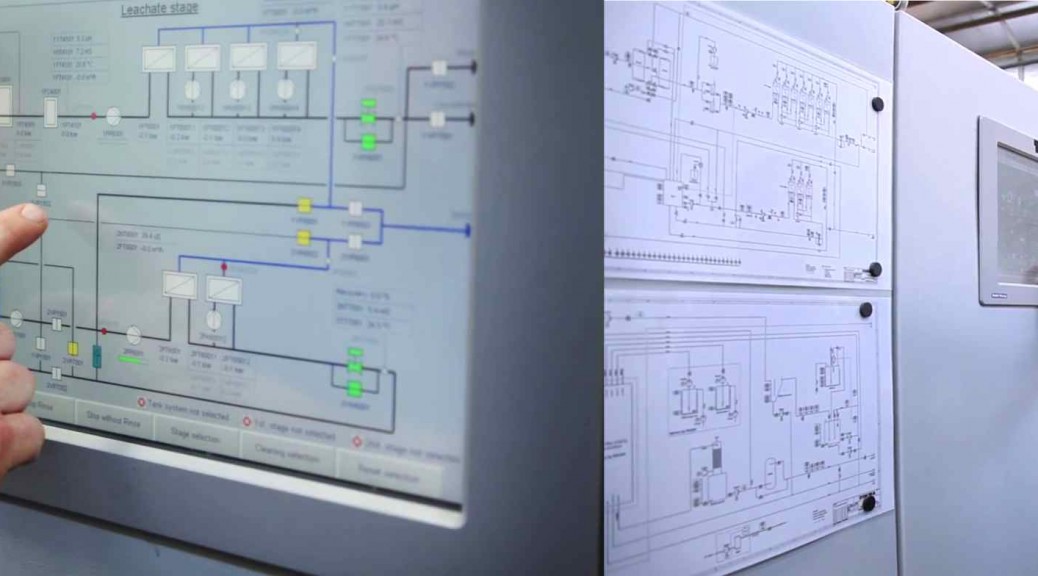

Every RO system supplied by RAO is completely assembled and fully tested prior to dispatch from the factory. Therefore they can be in full operation literally just a few hours after arriving on site. There are only four fixed or flexible pipe connections to make plus an electrical supply. Nothing else.

The ROCHEM® RO Fresh Water Generators are designed, fabricated and approved according to the following National and International Standards:

DIN – (German Industrial Standard) VDE – (Association of German Electricians) VDMA – (Organisation of German Mechanical Engineers) IEC – International Electric Standards for Electr. Motors ISO – International Standards

The ROCHEM® RO units are designed and constructed to fulfil the requirements of the following Classification societies:

Germanischer Lloyd Lloyd’s Register of Shipping American Bureau of Shipping Det Norske Veritas Bureau Veritas

ROCHEM ASIAN OPERATIONS since 1993.

ROCHEM ASIAN OPERATIONS since 1993.