| 1. Pump out the oil from the tank which needs cleaning to another tank |

There are 2 types of oil in the tank which needs cleaning: clean oil and sludge oil. Sludge is normally at the bottom of the tank. Thus, it’s necessary to pump out clean oil to another tank before treating sludge oil. IMP: pump just enough, avoid clean oil being contaminated by sludge. |  |

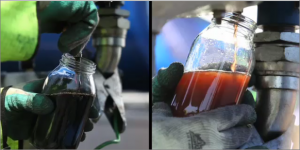

| 2. Check quality of the remaining oil and percentage of sludge |

| After pumping clean oil to another tank, the remaining oil is sludge oil containing contaminant. Carry out checking quality and percentage of sludge to determine the level of contamination. |

| 3. Pump out the oil sludge at the bottom of the tank |

| After having the result of oil quality and sludge percentage, carry out pumping out oil sludge from the bottom of the tank to another tank. |  |

| 4. Open all windows of the oil tank and ventilate the tank |

| After pumping out oil sludge at the bottom of the tank, open all the tank’s windows and ventilate it. (natural ventilation or with fan or air blower).

IMP: Check concentration of H2S, CO, O2 in the tank by portable gas measuring instruments before let workers come in (H2S = 0, CO = 0 …) and must comply with safety procedures. |

| 5. Install pumps and their pipes, install and use clean oil to clean |

| Install piping system of high pressure pump, DO oil supply piping for cleaning (cleaner), pump system (diaphragm pump, centrifugal pump...) | |

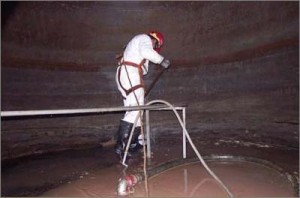

| 6. Let sanitation worker come in |

Sanitation workers must be equipped with oxygen masks, tight protective equipment (use tape to seal gap between boots, gloves and protective clothing)

IMP: establish priority area: emergency area, internal area… Always ready for emergency cases such as suffocation, fainting, get the victim out of the dangerous places… |

|

| 7. Clean the entire tank bottom and construct scaffold in the tank |

Sanitation workers collect residual sludge in tank with dedicated tools, construct scaffold for wall and top cleaning. After collecting oil sludge, pump out the collected oil sludge as much as possible. |  |

| 8. Transport and provide sanitation workers with cleaning gun… |

| Provide cleaning gun, prepare for operating high pressure pump, cleaner to prepare for cleaning oil sludge clinging to the bottom, wall and top of the tank. |

| 9. Clean the tank with cleaner |

| Let the clean DO (cleaner) go through high pressure vessel to clean the entire bottom, wall and top of the tank. Sanitation workers use gun to eject DO with high pressure on the surface clung by oil sludge. |

| 10. Pump out all oil sludge and clean again with cloths, scrapers and gas |

| Pump out all oil sludge which has been cleaned from the bottom, wall and top of the tank. Check the tank after cleaning, if oil still contains oil sludge, use cloths, scrapers and compressed air to clean again to ensure remove maximum oil sludge in the tank. |  |

| 11. Collect entire contaminants and equipment |

Collect oil sludge to treat, protective equipment, pipe, scaffold, pump…. Check the checklist to ensure all equipment are collected. IMP: Clean equipment for the next use. |

| 12. Install windows and pump clean oil into the tank |

| Install all windows and pump clean oil from the container into the tank. IMP: windows of the tank need installing properly technically |  | |

| 13. Collect sludge and dirty oil… at the site to treat |

| Collect sludge, use specialized vehicle to transport to the treatment site. |

|