REDUCING ENVIRONMENTAL RISK OF LANDFILLS: LEACHATE TREATMENT BY REVERSE OSMOSIS

REDUCING ENVIRONMENTAL RISK OF LANDFILLS: LEACHATE TREATMENT BY REVERSE OSMOSIS

Ana-Maria Şchiopu (1,2), George Ciprian Piuleac (1), Corneliu Cojocaru (3), Ion Apostol (2), Ioan Mămăligă (1), Maria Gavrilescu (1,3)

(1) ”Gheorghe Asachi”Technical University of Iasi, Department of Environmental Engineering and Management, 73 Prof.dr.docent Dimitrie Mangeron Street, 700050 Iasi, Romania

(2) S.C. Salubris S.A. Iasi, 43 National Road, Romania

(3) Institute of Macromolecular Chemistry “Petru Poni”, Aleea Grigore Ghica Voda 41 A, 700487 Iasi, Romania 4Academy of Romanian Scientists, 54 Splaiul Independentei, RO-050094 Bucharest, Romania

Abstract

Sanitary landfilling is nowadays the most common way to eliminate municipal solid wastes, although waste management hierarchy considers landfilling as a last option. The resultant leachate produced due to waste transformation and rainfall can be identified by specific characteristics and variables, corresponding to high-strength wastewaters, which generate impacts and risks in the environment. This situation imposes stringently leachate treatment by appropriate and efficient methods and processes.

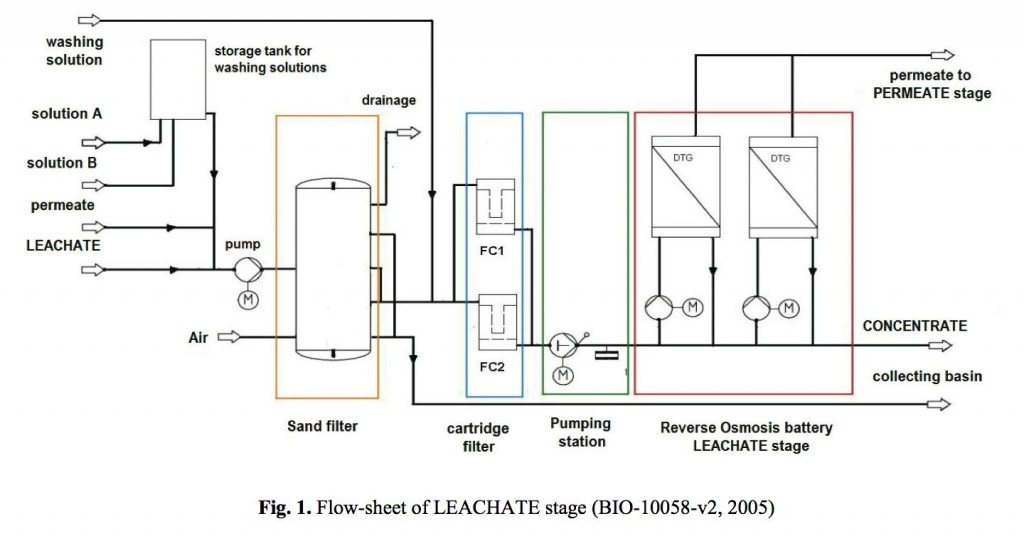

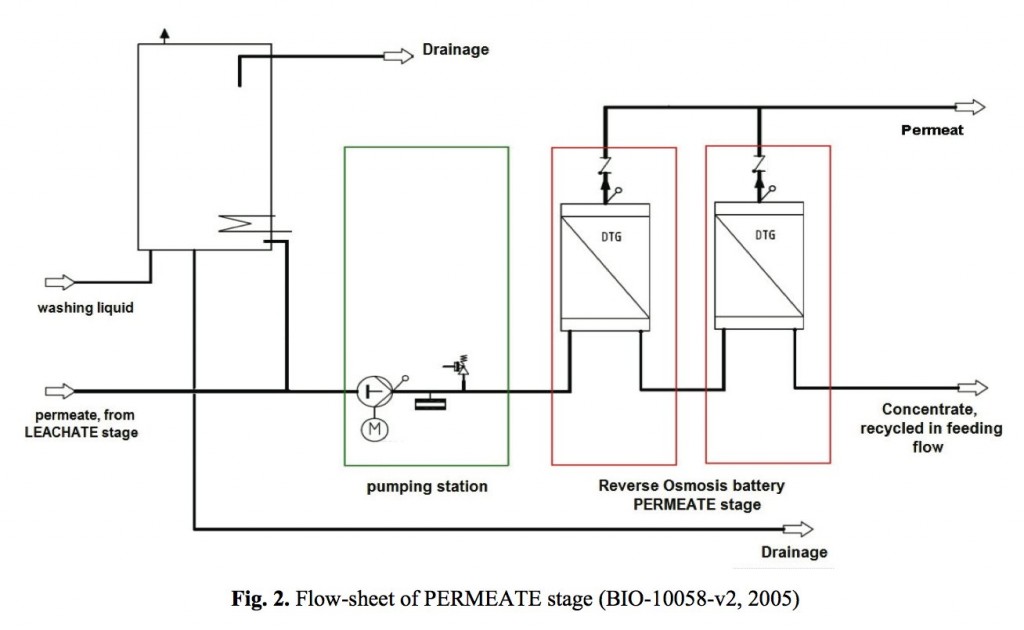

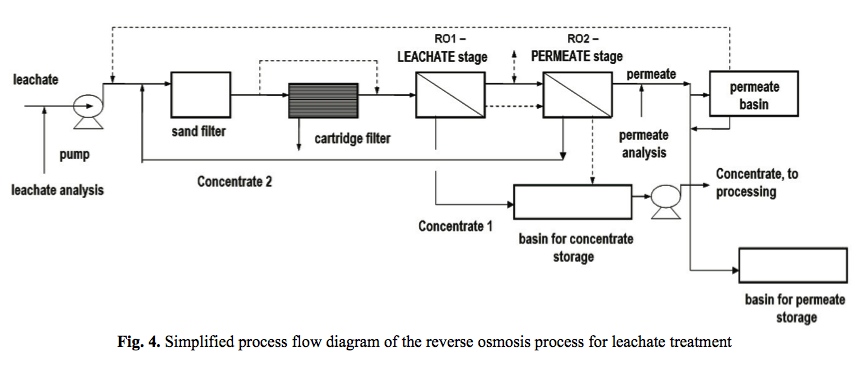

This research analyzes the performance of a municipal waste landfill leachate treatment system applying a membrane process - reverse osmosis (RO), for almost a year of operation. The system equipped with disc-tube (DT) membrane modules, and located in the sanitary landfill of the city of Iasi, Romania includes two stages: LEACHATE stage and PERMEATE stage, preceded by a pre-treatment module consisting of sand and cartridge filters. A storage system is included in the flow-sheet, for cleaning agents and various chemicals. Pumping stations provide the necessary operating pressure in the system.

A removal efficiency of contaminants (COD, NH4+, electrical conductivity etc.) exceeding 90% was achieved. Any variation in permeate flux (14-22 L/m2h) and separation efficiency (94-100%) was due to increasing osmotic pressure and fouling, scaling and polarization of concentration.

The RO process demonstrated a high rejection rate for both organic and inorganic contaminants dissolved in the leachate, together with a high flexibility alongside the changes in the leachate composition, depending on pressure, temperature, pH feeding flow rate of leachate.

1. Introduction

Nowadays, landfilling continues to be the most common option to eliminate municipal solid waste (MSW), although waste management hierarchy considers landfilling as a last option for disposing both municipal and some solid industrial waste (Chen et al., 2011; Chen et al., 2012; Cordente-Rodriguez et al., 2010; Eskandari et al., 2013; Fortuna et al., 2011; Rada et al., 2010; Schiopu and Gavrilescu, 2010a;

Taboada-Gonzalez et al., 2011). Although many advantages of landfilling have been highlighted over the years, landfill outputs induce impacts and risks in the environment, forcing authorities to impose more and more stringent constraints (EC Directive, 2008; HPA, 2011; Ghinea and Gavrilescu, 2010; Ghinea et al., 2012; Petraru and Gavrilescu, 2010).

The generation of leachate, which is similar to a heavily contaminated wastewater is one of the most challenging problems in landfill management

(Omran and Gavrilescu, 2007; Pitchel, 2005; Schiopu et al., 2007; Schiopu and Gavrilescu, 2010a, b). This liquid stream is a mixture of organic and inorganic contaminants, including humic and fulvic acids, inorganic and organic compounds containing nitrogen, heavy metals, xenobiotics and inorganic salts, which must be removed due to their toxicity or adverse effects that their presence can induce in the environment (Abbas et al., 2010; Andreottola and Cannas, 1992; Aziz et al., 2012; Liu et al., 2011; Moy, 2005; Sir et al., 2010; Zaharia and Suteu, 2011).

Despite extensive scientific literature on the collection, storage and suitable treatment of the highly contaminated leachate, some aspects of leachate treatment and management still need to be enhanced and optimized. Research in this area continues to develop, since the treatment of landfill leachate is an increasingly significant environmental concern, and stricter environmental requirements are permanently enforced, especially those regarding ground and surface waters (European Directive 1975/440/EC on surface waters –Water Framework Directive), (EC Directive, 2000) has generated interest about the sources of contamination of the aquatic ecosystem.

The complexity of the problem increases as lower concentrations of pollutants in the treated effluent are imposed, given that the composition and volumetric flow of leachate are dependent on the climatic condition, waste characteristics and the age of the landfill (Pohontu et al., 2010; Schiopu and Gavrilescu, 2010a; . As a consequence of this trend, landfill effluent treatment - particularly leachate is an important objective for landfill operators, so that the system would meet effluent quality standards for discharging into municipal sewage systems or natural receptors (Schiopu and Gavrilescu, 2010a; Tchobanoglous and Kreith, 2002).

V arious treatment alternatives are applied for leachate treatment, such as: leachate transfer, biodegradation, chemical and physical methods, membrane processes (Cailean et al., 2009; Pohontu et al., 2011; Renou et al., 2008; Trebouet et al., 2001; Wang et al., 2001; Yetilmezsoy et al., 2011). Microfiltration, ultrafiltration, nanofiltration and reverse osmosis are the most commonly used membrane processes for leachate treatment (Barjoveanu and Teodosiu, 2010; Cascaval and Galaction, 2010; Musteret et al., 2010; Podaru et al., 2008; Uygur and Kargi; 2004). Reverse osmosis is one of the most promising and efficient methods among the new processes for landfill leachate treatment (Schiopu and Gavrilescu, 2010b; Thörneby et al., 2003; Ushikoshi et al., 2002; Williams, 2003). It is a separation process that uses pressure to force a solution through a membrane that retains the solute on one side and allows the pure solvent to pass to the other side.

Reverse osmosis (RO), also known as hyper filtration is actually a membrane separation technique operating at high pressure, energy efficient, applied to remove water from process streams, the concentration

of low-molecular substances existing in solution or purification of water (Bhattacharyya and Williams, 1992; Li et al., 2009; Williams, 2003; Wiszniowski et al., 2006). The method is able to concentrate all solutions and solids in suspension. Reverse osmosis membranes are able to separate ions, organic compounds containing oxygen and nitrogen, pesticides, colloids with sizes below 3.10 m (Lee et al., 2011; Teodosiu, 2001). Permeate contains low concentrations of dissolved solids.

In the '70s - '80s numerous studies and feasibility analyses were conducted on the applicability of reverse osmosis to treat leachate from landfills (Abbas et al., 2009; Chianese et al., 1998; Englehardt et al., 2006). Chian et al. (1976) found that reverse osmosis is the most effective method for reducing the COD from leachate. Experimental studies of Krug and McDongall (1989), Kinman and Nutini (1991), Bilstadt and Madland (1992) showed that reverse osmosis based technology is feasible for treating leachate, reporting values of the retention efficiency of COD and heavy metals of 98% and 99% respectively. Therefore, RO can be applied successfully to treat leachate (Abbas et al., 2009; Englehardt et al., 2006; Kurniawan et al., 2006; Lee et al., 2011; Ushikoshi et al., 2002). COD removal efficiency can reach values of 98-99%.

The first type of membrane used since 1984 were tubular or spiral configuration (Abbas et al., 2009). Studies performed both at laboratory and industrial scales to investigate the performance of different types of reverse osmosis membrane modules have shown that the tubular membrane modules, which are the most frequently used for leachate treatment by reverse osmosis, had some disadvantages. They offer a lower permeate recovery rate and a rather low membrane packaging density, which can result in an excessive number of membrane tubes and a large space required for deployment. Further studies on leachate treatment by reverse osmosis demonstrated that the disc tube reverse osmosis (DT-RO) module could be regarded as more efficient for leachate purification (Peters, 2010; Renou et al., 2008; Schiopu, 2010).

The first extensive study of the performance of a leachate treatment system by reverse osmosis using disc-tube systems is dating since 2002, which highlights the great flexibility, reliability and their excellent maintainability. This study does not make available to specialists feasible tools such as modeling and simulation, enabling optimal operation of the system (Ushikoshi et al., 2002). Another study since 2005 marks out the advantages of the disc-tube systems applications (DT-RO) for the treatment of leachate, observed both experimentally and on qualitative analysis of influencing factors (Liu et al., 2005). This study evaluated the qualitative operation of a leachate treatment plants by reverse osmosis with disc-tube modules, in a landfill in China, after six months of operation, they notice that its performances are very good and stable. Liu et al. (2008), experimented a reverse osmosis system with the disc-

tube module (DT-RO) applied to treat landfill leachate on full scale at the Changshengqiao Sanitary Landfill, Chongqing City, China, and investigated the DT-RO system performance and the measures to control membrane fouling. The removal efficiency of some organic and inorganic pollutants exceeded 98% (Liu et al., 2008). The study of Sir et al. (2012) deals with the treatment of hazardous waste landfill leachate originating from a landfill located in an abandoned brown coal pit in northern Bohemia. Specifically, the effect of humic acids on the DT-RO performance was studied, quantified as permeate flow and total rejection of leachate components, which were adversely affected by membrane fouling mainly due to the influence of humic acids.

The aim of this research is to analyze the performance of a leachate treatment system applying a membrane process - reverse osmosis, one of the most promising and effective techniques for treating landfill leachate. In this study, we investigated the performance of a full scale reverse osmosis system, equipped with disc-tube membrane modules, and located in the sanitary landfill of the city of Iasi, Romania. The paper discusses the DT-RO system performance, which is built on the principle of frame and plate filters, manufactured by West German Research Center in Geesthacht (GKSS), and then improved by ROCHEM. At this stage, the experimental part addresses the analysis of the factors with major influence on the system performance regarding separation efficiency and permeate flow rate.

2. Experimental

2.1. Experimental setup

Leachate treatment unit is placed in the Tutora landfill area of Iasi City, with road access. The treated effluent is discharged into a natural receptor and therefore must meet the requirements set by GD 325 (2005), in particular NTPA-001/2005 norm.

|

The DT-RO system is devoted to leachate treatment only (desalination cannot be carried out). The RO flow-sheet includes two stages (Schiopu, 2010):

(1) LEACHATE stage (which includes a leachate pretreatment on sand filters and cartridge filters and the first stage of RO) (Fig. 1).

(2) PERMEA TE stage (where an advanced purification of leachate is performed).

The reverse osmosis unit is connected to a pump station that generates pressure for reverse osmosis development. In this way the flow of the liquid phase is maintained in the reverse osmosis module, ensuring a permanent internal circulation. The resulting permeate from the LEACHATE stage is transported for the advanced treatment stage. The concentrate obtained is recirculated into the power supply. Permeate is stored in the dedicated tank.

A storage system is included in the flow- sheet, for cleaning agents and various chemicals necessary in the system, during pretreatment and post-treatment phases. Also, the storage segment contains all the necessary containers for feeding the system with leachate, for temporary storage of primary concentrate till the final disposal, and permeates storage (BIO-10058-v2, 2005).

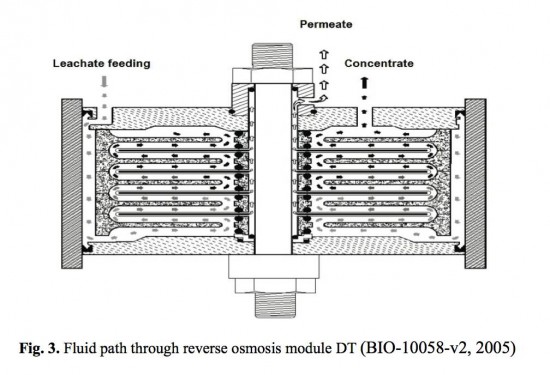

2.2. Reverse osmosis membranes and modules

Tube type modules with discs (disc-tube, DT) are the main components of the reverse osmosis plant. Fluid dynamics within the reverse osmosis module contributes substantially to the reduction of clogging and scales on membranes. The arrangement of disks inside the module, the main parts and the system inputs and outputs are shown in Fig. 3. Each reverse osmosis module contains 210 discs and 209 membranes (BIO-10058-v2, 2005; Schiopu, 2010).

As the leachate pressure reaches the membranes, reverse osmosis occurs and permeate passes through the membrane and is discharged through a permeate collector.

|

|

2.3. Experimental procedure

The study addresses the retention efficiency during a year of operation. Leachate from the landfill, combined with water from precipitation is conveyed by gravity to the side of the storage cell. Then, it is directed to a collection pit located near the leachate storage pond. Flow occurs on the principle of communicating vessels. Leachate is pumped into an equalization basin, where sedimentation of suspended solid particles occurs.

This basin also has the role of a backup storage tank for any rinsing operations (Fig. 4). Before beginning leachate treatment, the pH value was adjusted at 6.5 to avoid the premature precipitation of hard water ions. Then, leachate is pumped into the sand filter where the particles larger then 50 m are retained. From here leachate is sent to the cartridge filter that retains the particles larger than 10 m. After pretreatment, leachate is sent to the first

stage of reverse osmosis, where it is applied a pressure that exceeds the osmotic pressure (between 10 and 60 bar) to generate the driving force for the membrane process. In this stage metal ions, inorganic salts, ammonium salts, organic compounds are retained, so that the electrical conductivity is reduced in the liquid phase. After the first RO stage a volume of permeat (P1) results. It requires a complete stage of purification, to reach the requirements for discharging in natural receptors. So, P1 is pumped into a second stage of RO.

The concentrate volume resulted after the first stage of RO (C1) is discharged in its collection tank and will be re-circulated in waste mass (landfill body). After passing through the second the retention is over 90%. Permeate (P2) resulted from the second stage of RO is pumped to the temporary storage tank, where a correction of pH (33% NaOH solution) is carried out to accomplish the discharge conditions under NTPA 001/2002 (GD 352, 2005).

|

The concentrate (C2) resulted from the second stage of RO is re-circulated into the system before the first stage2of RO. The permeate flux varied between 14-22 L/m h, due to membrane fouling. It was found that the low limit of permeate flux could be increased by prefilternig the leachate (using sand and cartridge filters), adding sulphuric acid into the leachate (which reduces pH to avoid water-hardness ion scaling), adding anti-scaling substances, membrane regeneration by chemical cleaning, optimizing the operating conditions (including ensuring a moderate operating pressure), cross flow, washing before system stop etc. The system exhibited a high rejection rate for both organic and inorganic contaminants dissolved in the leachate, together with a high flexibility against the changes in the leachate composition.

2.4. Separation factor

The separation factor of any solute, R is expressed by the relation (1):

R = 1 (Cp / Cs) x 100 (1)

where:

Cp - solute concentration passing through the membrane (permeate once) (mg/L)

Cs - solute concentration in the feeding stream (mg/L)

3. Results and discussions

3.1. Characteristics of leachate

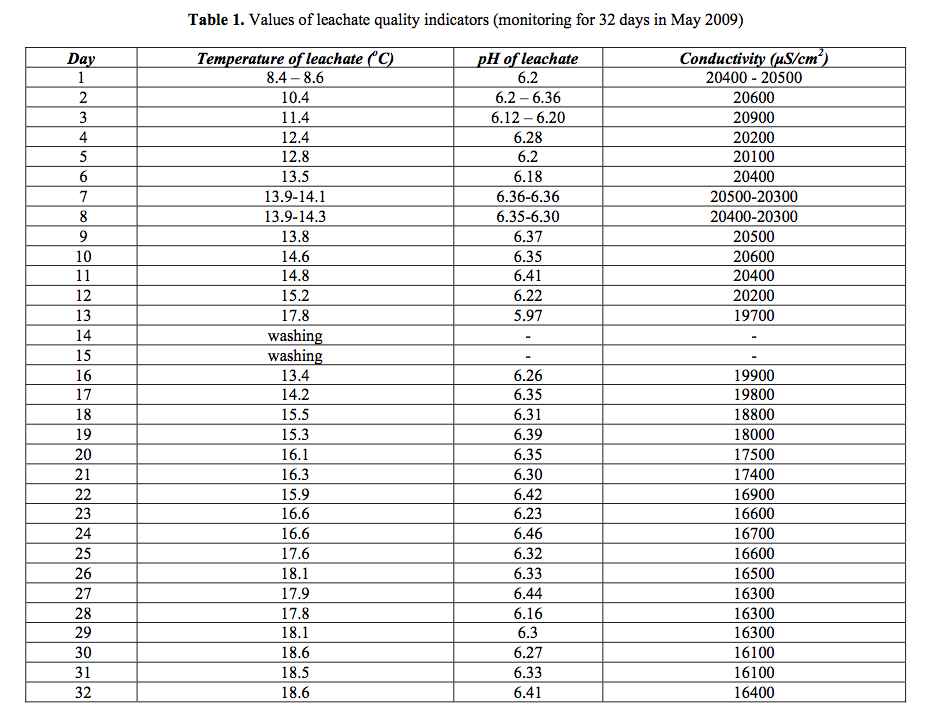

To achieve the experimental program for leachate treatment using the reverse osmosis system described above, leachate with characteristics of young leachate was supplied. Monitoring during 32 consecutive days of leachate quality indicators entering reverse osmosis plant, showed that they vary within relatively wide limits, as can be seen from Table 1. The leachate was first analyzed considering

the following indicators: NH4+ (320-1600 mg/L); electrical conductivity (15000-24000 Scm-1); CODCr (700-3600 mgO2/L).

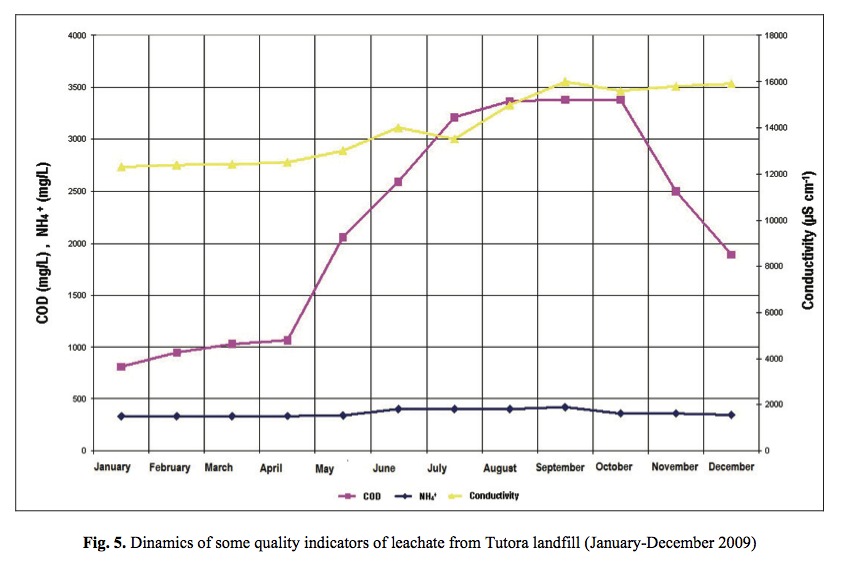

The values of the indicators showed considerable variation, due to the physico-chemical and biological process dynamics occurring inside the landfill, which depend on the waste characteristics and seasonal parameter variations (Fig. 5). These variations depend largely on the dynamics of physico- chemical and biological processes occurring in the landfill, significantly influenced by seasonal variations in temperature and rainfalls (Omran and Gavrilescu, 2008; Schiopu, 2010; Tchobanoglous and Kreith, 2002).

Studies and analyzes conducted during January to December 2009 showed large variations of COD values (which quantifies the presence of organic compounds in leachate) with a maximum during June to September (3000-3500 mgO2/L) with values around 1000-2000 mg / L during the cold season. Less significant variations were found in the values of NH4+ concentrations. Electrical conductivity values are higher in the second half of the period (September-December), probably due to abundant rainfalls that increased dynamics of dissolved inorganic salts landfill (Fig. 5).

3.2. Factors affecting RO performance and separation efficiency

3.2.1. Influence of operating pressure on permeate flow rate and quality

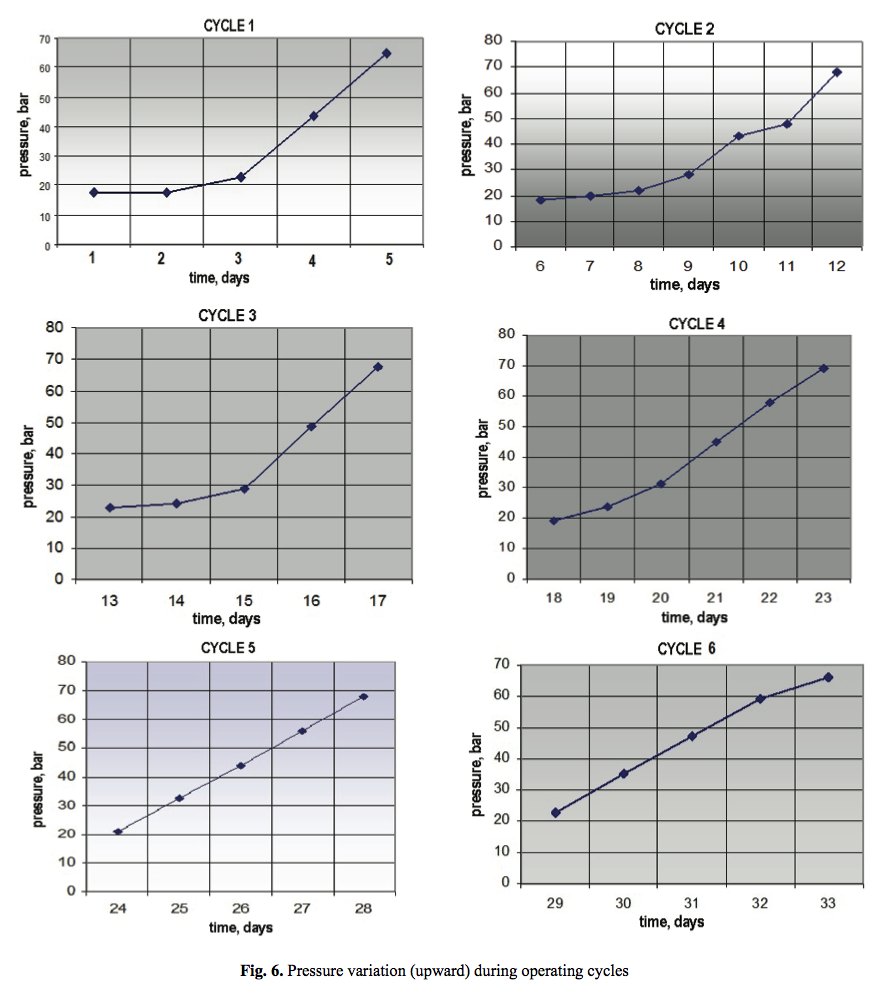

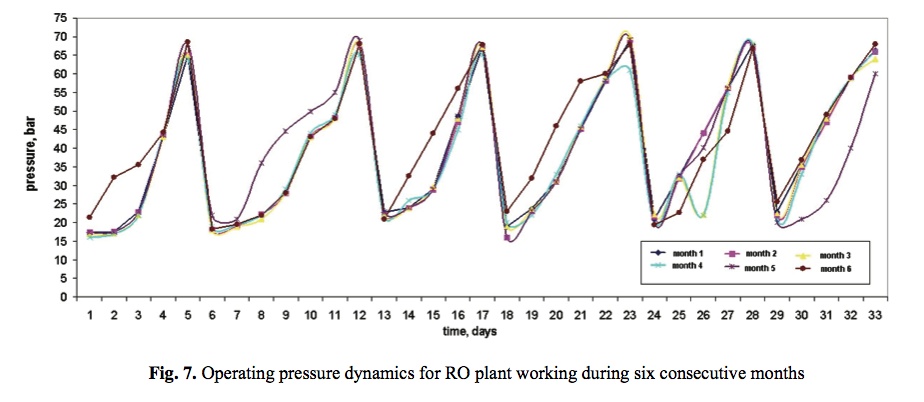

It was found that the working pressure increases from values between 10-20 to 60-70 bar during a working cycle, which lasts about five days. Observations were made during 6 cycles for 30 days. Pressure variation over time is illustrated in Fig. 6, which shows that the pressure profiles differ from one cycle to another, due to the performance of washing operation conducted at the end of each operating cycle. This alternation between operating-washing cycles is shown in Fig. 7.

|

|

|

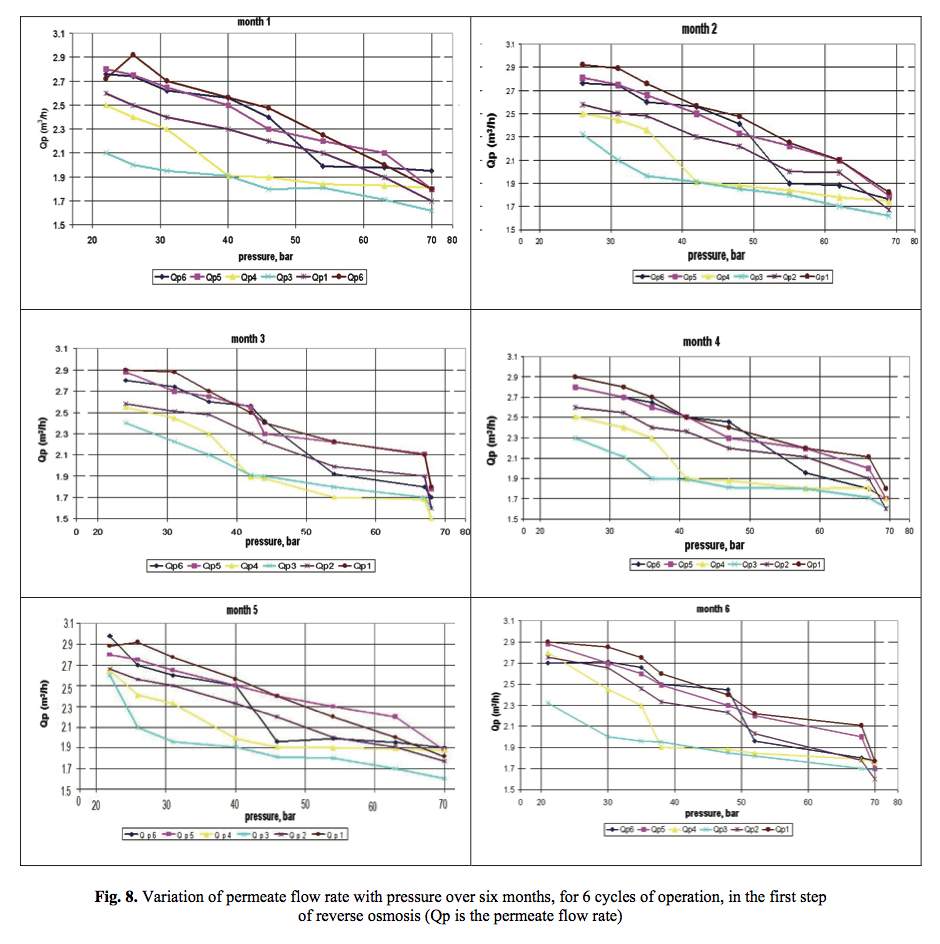

The monitoring of operating pressure during six months confirms that its variations are the consequence of the performance of washing operation, but also of leachate loading with pollutants. The analysis and monitoring of leachate quality indicators (electrical conductivity, COD, NH4+) (Table 1, Fig. 5) confirm the variation in leachate loading, which can affect the operating pressure dynamics during RO. While increasing the operating pressure as a result of lowering membrane permeability by clogging and fouling, a decrease in permeate flow rate occurs.

Fig. 8 illustrates this situation, for operating cycles recorded during six months of

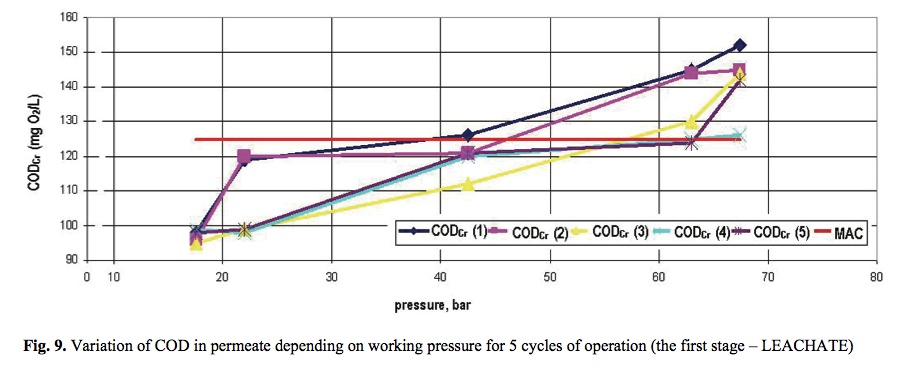

experimentation. Permeate flow rate decreasing at the end of the PERMEATE stage was of 30-50%. Decreased membrane permeability during the operating cycle due to clogging and scaling affects the permeate flow rate and quality due to differential retention of ionic species and other contaminants (Kim et al., 2003; Schiopu, 2010). One of the most relevant indicators of quality of permeate, Chemical Oxygen Demand (expressed by CODCr) shows variations of ±20% compared to the Maximum Allowable Concentrations (MAC, according to HG 352, 2005), depending on the operating pressure (Fig. 9).The plots in Fig. 9 show that, COD values are significantly below the MAC up to a pressure of 40

bar. After that, COD increases, depending on the operating cycle, the washing performance, and leachate loadings. This behavior was similar during 6 months of experiments, in the first stage (LEACHATE) of RO. The flux rate of the permeate through the membrane depends on the COD factor (Chianese et al., 1999; Schiopu, 2010).

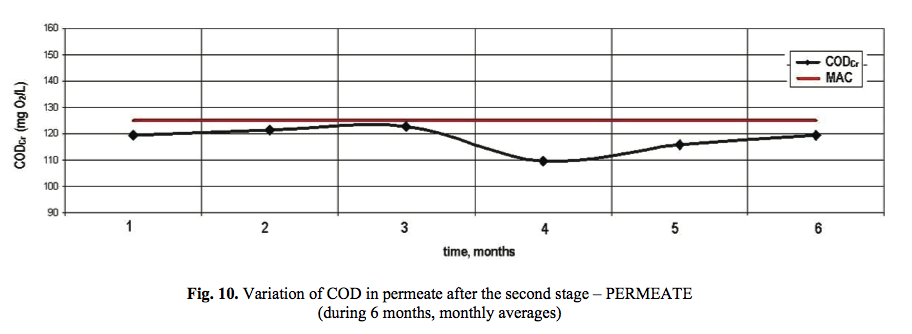

The dynamics of COD recorded after the second stage of RO (PERMEATE stage), during 6 months of experimentation, indicate that, although there are variations between ± (4.5 to 7.5)% compared to an average value of COD, it is below MAC value, quality permeate falling within the provisions of NTPA-001/2005 (Fig. 10). The good COD rejection of 94%–96% had also demonstrated the performance of reverse osmosis (DT-RO) with a wide range of COD concentrations from 700–3500 mgO2/L. Similar results were reported in literature (Liu et al., 2005; Liu et al., 2008).

From Figs. 6 - 10 it is evident that the pressure is a parameter with major influence on the efficiency of separation of contaminants existing in landfill leachate. Increased pressure in the system is needed to counteract the effects of phenomena that occur at the membrane surface (fouling and polarization of concentration), that increase the permeate osmotic pressure.

These phenomena lead to lower separation ability of the membrane and consequently different amounts of solute will pass with permeate, whose flow will decrease with increasing pressure, from the above mentioned reasons.

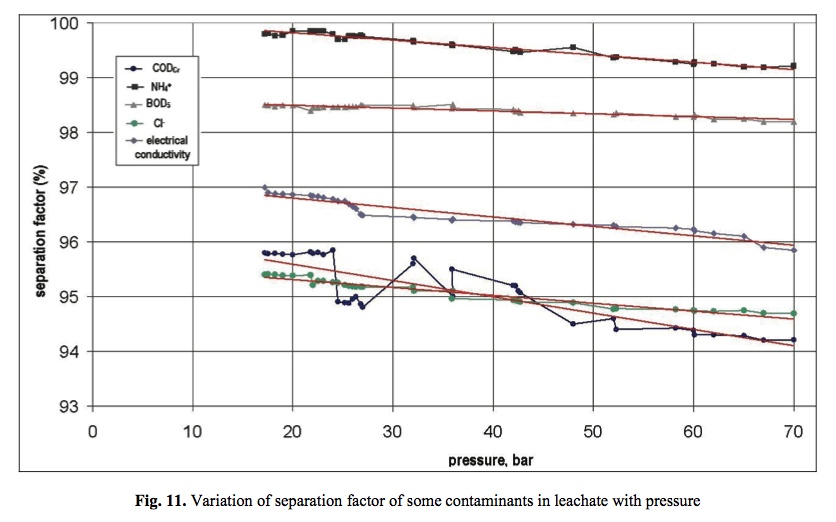

Under these circumstances we can talk about a variation of the separation factor with the operating pressure: it diminishes as the pressure increases, so as to counteract increased osmotic pressure of the permeate value, as a consequence of the polarization of solute concentration at the membrane surface. Fig. 11 confirms, based on experimental data, the behavior of the system, showing that that separation factor has a descending trend with the pressure increasing, for all contaminants in leachate considered for separation.

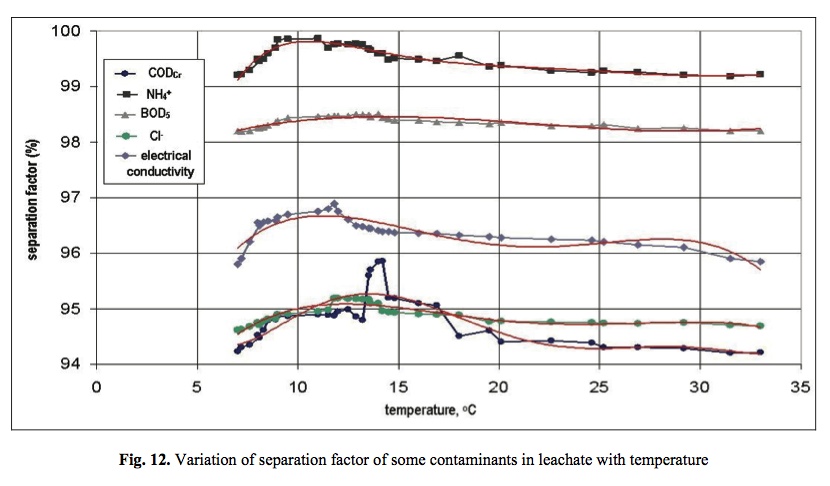

3.2.2. Influence of temperature on separation factor

Leachate temperature significantly affect, in a favorable way, the separation factor, but only in the interval 5-17oC. After that temperature no longer affect the separation process in a significant measure (Fig. 12). This relatively constant variation of the separation factor with temperature is the result of adverse effects that cancel each other: increasing temperature leads to a decreasing in membrane resistance for permeate (possible due to reduced viscosity of the liquid phase), but also for contaminants.

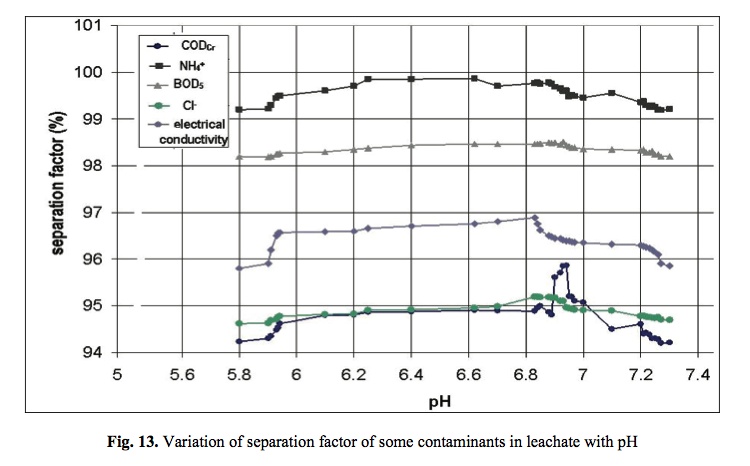

3.2.3. Influence of pH on separation factor

Leachate pH influences the separation factor between, for pH = 5.8 – 6.0 and that 6.8 – 7.3. Constant values of the separation factor can be found in the pH range 6.0 – 6.8 (Fig. 13). Acidic pH values change the equilibrium of ammonium ion in gas and liquid phases. NH4+ can form ammonium salts with anions, such as HCO32-, SO42- having positive impact on NH3-N retention from leachate. As shown in Fig. 12, NH4+ removal by DT-RO was very high, since the separation factor exceeded 99%.

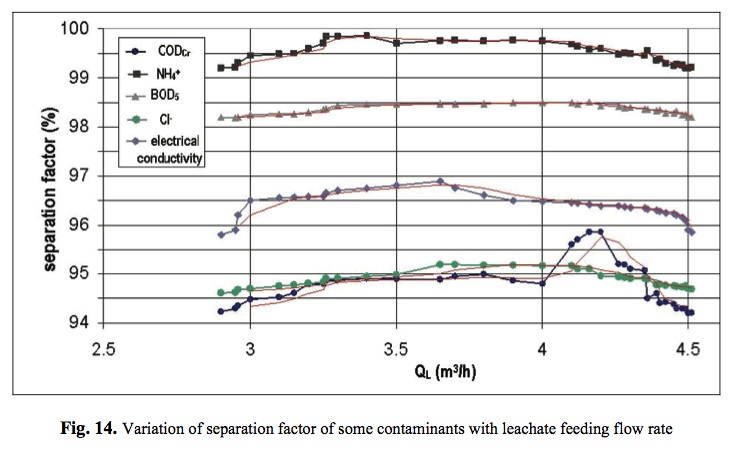

3.2.4. Influence of leachate feeding flow rate on separation factor

The evolution of separation factor during RO cycles is determined by the variations in the leachate flow rate, since it determines the variation of membrane permeability as a consequence of an increasing balance of the contaminants needed to be separated (Fig. 14). As a consequence, the phenomena that occur on the membrane surface (fouling and polarization of concentration), caused also by the other factors mentioned above, will be even more intense whether the quantities of contaminants and permeate will increase. As a consequence, the events that occur on the membrane surface (fouling and concentration polarization), caused also by other factors mentioned above, will be even more intense as the quantities of contaminants and solvent (permeate) will increase.

|

|

|

|

|

|

|

|

4. Conclusions

The treatment of landfill leachate by reverse osmosis shows that this method is a feasible and effective alternative to provide good efficiency of separation, especially when the leachate with complexe composition is processed.

Disc-tube module RO system is an innovative concept in the context of the application ofmembrane processes to treat leachate. The experiments were conducted on an industrial scale RO disc-tube module plant, located in the area of Tutora landfill, managed by Iasi municipality. The treated effluent is discharged in a natural receptor, since it fulfills the provisions of Romanian regulations.

A high flexibility of the system alongside the variation of the concentration of the compounds of landfill leachate was obtained, as the system demonstrated high rejection rate for both organic and inorganic contaminants in leachate. Even if the quality indicators of raw leachate ranged on a large area, the rejection rate of CODCr, Cl-, NH4+, electric conductivity were maintained over 94%.

Acknowledgement

A part of this paper was elaborated with the support of a grant of the Romanian National Authority for Scientific Research, CNCS – UEFISCDI, project number PN-II-ID- PCE-2011-3-0559, Contract 265/2011.

The co-author Corneliu Cojocaru is grateful to the research project STREAM, (Grant Agreement no. 264115, call FP7- REGPOT-2010-1)

References

Abbas A.A., Jingsong G., Ping L.Z., Y a P .Y ., Al-Rekabi W.S., (2009), Review on landfill leachate treatments, Journal of Applied Sciences Research, 5, 534-545.

Andreottola G., Cannas P., (1992), Chemical and Biological Characteristics of Landfill Leachate, Chapter 2.4, Landfilling of Waste: Leachate, Elsevier Applied Science, London and New York.

Aziz H.A., Adlan M.N., Amilin K., Yusoff M.S., Ramly N.H., Umar M., (2012), Quantification of leachate generation rate from a semi-aerobic landfill in Malaysia, Environmental Engineering and Management Journal, 11, 1581-1585.

Barjoveanu G., Teodosiu C., (2010), Modeling and simulation of an ultrafiltration process for the removal of suspended solids and colloids from wastewater, Environmental Engineering and Management Journal, 9, 361-371.

Bhattacharyya D., Williams M., (1992), Introduction and Definitions - Reverse Osmosis, In: Membrane Handbook, Ho W., Sirkar K., (Eds.), Van Nostrand Reinhold, New York, 265-268.

BIO-10058-v2, (2005), Master Plan – Aplication ISPA, Iaşi, România.

Bilstad T., Madland M.V., (1992), Leachate minimization by reverse osmosis, Water Science and Technology, 25, 117 – 120.

Cailean D., Teodosiu C., Brinza F., (2009), Studies regarding advanced processes used for reactive dyes removal from textile effluents, Environmental Engineering and Management Journal, 8, 1045-1051.

Cascaval D., Galaction A. I., (2010), Recovery of nicotinic acid from industrial effluents by facilitated pertraction, Environmental Engineering and Management Journal, 9, 1195-1201.

Chen H.B., Zhang L., Zhou J.C., Hu Y., (2011), Development of municipal solid waste management practices in different geographical units and urban systems in China, Environmental Engineering and Management Journal, 10, 945-949.

Chen K.S., Chen R.H., Liu C.N., (2012), Modeling municipal solid waste landfill settlement, Environmental Earth Sciences, 66, 2301-2309.

Chian E.S.K., Asce M., De Walle F.B., (1976), Sanitary landfill leachate and their treatment American Society of Civil Engineering, Environmental Engineering Divisions Journal, 102 (EE), 415 - 431.

Chianese A., Ranauro R., Verdone N., (1998), Treatment of landfill leachate by reverse osmosis, Water Research, 39, 647 – 652.

Cordente-Rodriguez M., Mondejar-Jimenez J.A., Meseguer-Santamaria M.L., Mondejar-Jimenez J., Vargas-Vargas M., (2010), Environmental behavior and selective waste management in Spanish housing, Environmental Engineering and Management Journal, 9, 1165-1171.

Englehardt J.D., Deng Y., Polar J., Meeroff D.E., Legrenzi Y., Mognol J., (2006), Options for Managing Municipal Landfill Leachate: Year 1. Development of Iron-Mediated Treatment Processes, Report #0432024- 06, State University System of Florida, Florida Center for Solid and Hazardous Waste Management, Gainesville, USA.

Eskandari M., Homaee M., Mahmodi S., (2012), An integrated multi criteria approach for landfill siting in a conflicting environmental, economical and socio- cultural area, Waste Management, 32, 1520-1538.

EC Directive, (2000), Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 establishing a framework for Community action in the field of water policy, Official Journal of the European Communities, L327, 1-72.

EC Directive, (2008), Directive 2008/98/EC of The European Parliament and of The Council of 19 November 2008 on waste and repealing certain directives, Official Journal of the European Union, L312, 3-30.

Fortuna M.E., Simion I.M., Gavrilescu M., (2011), Sustainability in environmental remediation, Environmental Engineering and Management Journal, 10, 1987-1996.

GD 352, (2005), Governmental Decision 352/2005 amending and supplementing the Governmental Decision no. 188/2002 approving the norms on discharging conditions of wastewater in aquatic environment, Romanian Official Monitor, 398/2005.

Ghinea C., Gavrilescu M., (2010), Decision support models for solid waste management - an overview, Environmental Engineering and Management Journal, 9, 869-880.

Ghinea C., Petraru M., Bressers H.T.A., Gavrilescu M., (2012), Environmental evaluation of waste management scenarios - significance of the boundaries, Journal of Environmental Engineering and Landscape Management, 20, 76-85.

HPA, (2011), Impact on Health of Emissions from Landfill Sites. Advice from the Health Protection Agency, Documents of the Health Protection Agency, Radiation, Chemical and Environmental Hazards, RCE 128, On line at: https://www.hpa.org.uk/webc/HPAwebFile/HPAweb_C /1309969974126

Kinman R.N., Nutini D.L., (1991), Reverse osmosis treatment of landfill leachate, The 45th Purdue Industrial Waste Conference Proceedings, Lewis Publishers, Chelsea, Michigan, 617 – 622.

Krug T.A., McDouglall S., (1989), Preliminary assessment of a microfiltration/reverse osmosis process for the treatment of landfill leachate, The 43rd Purdue Industrial Waste Conference Proceedings, Lewis Publishers, Chelsea Michigan, 185 – 193.

Kurniawan T.A., Lo W.-H., Chan G.Y.S., (2006), Physico- chemical treatments for removal of recalcitrant contaminants from landfill leachate, Journal of Hazardous Materials, 19, 80-100.

Lee K.P., Arnot T.C., Mattia D., (2011), A review of reverse osmosis membrane materials for desalination— Development to date and future potential, Journal of Membrane Science, 370, 1-22.

Li F., Wichmann K., Heine W., (2009), Treatment of the methanogenic landfill leachate with thin open channel reverse osmosis membrane modules, Waste Management, 29, 960–964.

Liu Y.-p., Li X.-j., Wang B.-z., (2005), Disc tube reverse osmosis process for refuse leachate treatment, Water & Wastewater Engineering, 31, On line at: https://en.cnki.com.cn/Article_en/CJFDTOTAL- JZJS200508015.htm

Liu Y., Li X., Wang B., Liu S., (2008), Performance of landfill leachate treatment system with disc-tube reverse osmosis units, Frontiers of Environmental Science & Engineering in China, 2, 24-31.

Liu Z.P., Guo J.S., Fang F., (2011), Transformation and fluorescence spectroscopy of dissolved organic matter (dom) in landfill leachate treated by combined process, Environmental Engineering and Management Journal,10, 913-918.

Moy P., (2005), a health risk comparison of landfill disposal

and waste-to-energy (WTE) treatment of municipal solid wastes in New York City (NYC), MSc Thesis, Mailman School of Public Health at Columbia University, On line at: https://www.seas.columbia.edu/earth/wtert/sofos/Moy_ ms_thesis.pdf

Musteret C.P., Cailean D., Barjoveanu G., Teodosiu C., (2010), An assessment of operational parameters for the removal of chlorophenols from wastewater, Environmental Engineering and Management Journal, 9, 1451-1457.

Omran A., Gavrilescu M., (2008), Municipal solid waste management in developing countries: a perspective on Vietnam, Environmental Engineering and Management Journal, 7, 469-478.

Peters T.A., (1995), Purification of Landfill Leachate with Reverse Osmosis and DT-Module, In: Membrane Technology: Applications to Industrial Wastewater Treatment, Caetano A., Maria Norberta De Pinho M.N., Drioli E., Muntau H., (Eds.), Kluwer, Dordrecht, The Netherlands.

Peters T., (2010), Membrane technology for water treatment, Chemical Engineering Technology, 33, 1233-1240.

Petraru M., Gavrilescu M., (2010), Pollution prevention, a key to economic and environmental sustainability, Environmental Engineering and Management Journal, 9, 597-614.

Pitchel J., (2005), Waste Management Practices: Municipal, Hazardous, and Industrial, CRC Press, Taylor & Francis Group, Boca Raton.

Podaru C., Manea F., Vlaicu I., Patroescu V., Danielescu C., Burtica G., (2008), Studies regarding surface water treatment using a microfiltration-ultrafiltration pilot plant, Environmental Engineering and Management Journal, 7, 711-715.

Pohontu C., Cretescu I., Secula M.S., Paduraru C., Tofan L., Macoveanu M., (2010), Integrated treatment of leachate from municipal waste solid landfill, Environmental Engineering and Management Journal, 9, 95-100.

Pohontu C., Cretescu I., Secula M.S., Macoveanu M., (2011), Response surface methodology for optimization of landfill leachate treatment using ion exchange resins, Environmental Engineering and Management Journal, 10, 357-366.

Rada E.C., Istrate I.A., Panaitescu V., Ragazzi M., Cirlioru T.M., Apostol T., (2010), A comparison between different scenarios of Romanian municipal solid waste treatment before landfilling, Environmental Engineering and Management Journal, 9, 589-596.

Renou S., Givaudan J.G., Poulain S., Dirassouyan F., Moulin P., (2008), Landfill leachate treatment: review and opportunity, Journal of Hazardous Materials, 150, 468–493.

Schiopu A.-M., Apostol I., Hodoreanu M., Gavrilescu M., (2007), Solid waste in Romania: management, treatment and pollution prevention practices, Environmental Engineering and Management Journal, 6, 451-465.

Schiopu A.-M., (2010), Studies on Municipal Solid Waste Management and Treatment of Some Effluents Resulting During Waste Landfilling, PhD Thesis, “Gheorghe Asachi” Technical University of Iasi, Romania.

Schiopu A.-M., Gavrilescu M., (2010a), Options for the treatment and management of municipal landfill leachate: common and specific issues, CLEAN: Soil, Air, Water, 38, 1101–1110.

Schiopu A.-M., Gavrilescu M., (2010b), Municipal solid waste landfilling and treatment of resulting liquid effluents, Environmental Engineering and Management Journal, 9, 993-1019.

Sir M., Podhola M., Patocka T., Honzajkova Z., Kocurek P., Kubal M., Kuras M., (2010), The effect of humic acids on the reverse osmosis treatment of hazardous landfill leachate, Journal of Hazardous Materials, 207- 208, 86-90.

Taboada-Gonzalez P., Aguilar-Virgen Q., Ojeda-Benitez S., Armijo C., (2011), Waste characterization and waste management perception in rural communities in Mexico: a case study, Environmental Engineering and Management Journal, 10, 1751-1759.

Tchobanoglous G., Kreith F., (2002), Handbook of Solid Waste Management, 2nd ed., McGraw-Hill.

Teodosiu C., (2001), Technology of Drinking and Industrial Water, Matrix Rom Press, Bucharest, Romania.

Thörneby L., Hogland W., Stenis J., Mathiassan L., Somogyi P., (2003), Design of a reverse osmosis plant for leachate treatment aiming for safe disposal, Waste Management and Research, 21, 424–435.

Trebouet D., Schlumpf J.P., Jaouen P., Quemeneur F., (2001), Stabilized landfill leachate treatment by combined physico-chemical nanofiltration process, Water Research, 35, 2935-2942.

Ushikoshi K., Kobayashi T., Uematsu K., Toji A., Kojima A., Matsumoto K., (2002), Leachate treatment by the reverse osmosis system, Desalination, 150, 121-129.

Uygur A., Kargi F., (2004), Biological nutrient removal from pre-treated landfill leachate in a sequencing batch reactor, Journal of Environmental Management, 71, 9- 14.

Wang P., Lau W.C.I., Fang H.P.H., (2001), Landfill leachate treatment by anaerobic process and electrochemical oxidation, Environmental Science, 22, 70-73.

Williams M.E., (2003), A brief history of reverse osmosis membrane technology, EET Corporation and Williams Engineering Services Company, Inc., On line at: https://www.eetcorp.com/heepm/RO_ReviewE.pdf.

Wiszniowski J., Robert D., Surmacz-Gorska J., Miksch K., Weber J.V., (2006), Landfill leachate treatment methods: A review, Environmental Chemistry Letters, 4, 51-61.

Zaharia C., Suteu D., (2011), Analytical control of soil and ground water quality on a northern Romanian landfill, Environmental Engineering and Management Journal, 10, 1693-1701.

Yetilmezsoy K., Turkdogan-Aydinol I., Gunay A., Ozis I., (2011), Post treatment of poultry slaughterhouse wastewater and appraisal of the economic outcome, Environmental Engineering and Management Journal, 10, 1635-1645.

Key words: landfill leachate treatment, ro rochem, reverse osmosis, rochem system