Reverse Osmosis Application for Metal Finishing Operations

|

Merit Partnership Pollution Prevention Project for Metal Finishers Galaya Srisuwan, and Poonpetch Thongchai |

||||||||||||||||||||||||||||||||||||

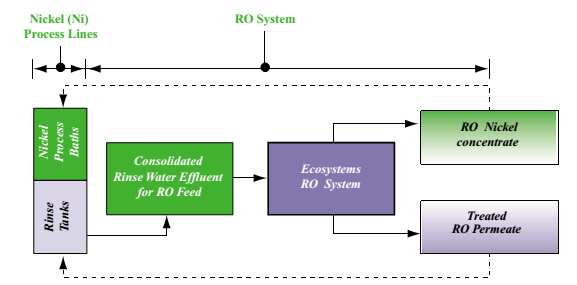

| RO applications for electroplating operations were mostly limited to final treatment of a combined wastewater stream. Such applications typically involved discharging the permeate to a POTW and returning the concentrate to the head of the wastewater treatment system. Because of the high flow rates associated with treating combined wastewater streams, large, RO units were required. More recent metal finishing applications of RO have involved installing RO units in specific process operations, allowing return of the concentrate (recovered chemical solution) to the process bath and reuse of the permeate (cleaned rinse water) as fresh rinse water. By “closing the loop”, valuable process chemicals are recovered, and less fresh water is needed. Furthermore, a waste stream is eliminated that would otherwise be discharged to the POTW. | ||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

Table 1. Industrial electroplating wastewater characteristics.

|

||||||||||||||||||||||||||||||||||||

| Heavy metals are important sources of environmental pollution. Some of them can form compounds which are toxic even in very low concentration. Even though the conventional techniques for organic compounds removal are biological and chemical treatment of the toxic materials degrades them to salts and CO2, the metals are permanent. The only way to remove them is to change their chemical and physical states by oxidation/reduction and precipitation. So far, there have been a number of researches that studied physical and chemical treatments. Membrane technology was one option for a nonpolluting process. The membrane of optimum pore sizes were capable of removing almost all pollutants without using any chemicals. Sludge obtained in the process contained only pollutant constituents in this feed stream. In order to increase the removal efficiency and reduce the operating cost, membrane technology was also used together with other treatment processes . | ||||||||||||||||||||||||||||||||||||

Related

Wastewater

Seawater