Pharmaceutical Wastewater Treatment

| INTRODUCTION | |||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

|

Physical/ chemical systems are a common method of treating pharmaceutical wastewater; however, system results are limited due to high sludge production and relatively low efficiency of dissolved COD removal. Biological aerobic treatment systems are also used extensively, often with limited success due to the final clarification step. The clarifiers are susceptible to sludge bulking and variations in total dissolved solids, often associated with batch process production, which can cause destabilization of bacterial floc formation, with a consequential loss of biomass in the final effluent. These systems require constant operator attention to adjust chemical dosing for the daily, even hourly changes in influent flow. |

|||||||||||||||||||||||||||||||||||||||||

| Table 1. Composition of Pharmaceutical Wastewaters | |||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

| MODERN WASTEWATER TREATMENT AT A PHARMACEUTICAL PRODUCTION ENVIRONMENT | |||||||||||||||||||||||||||||||||||||||||

|

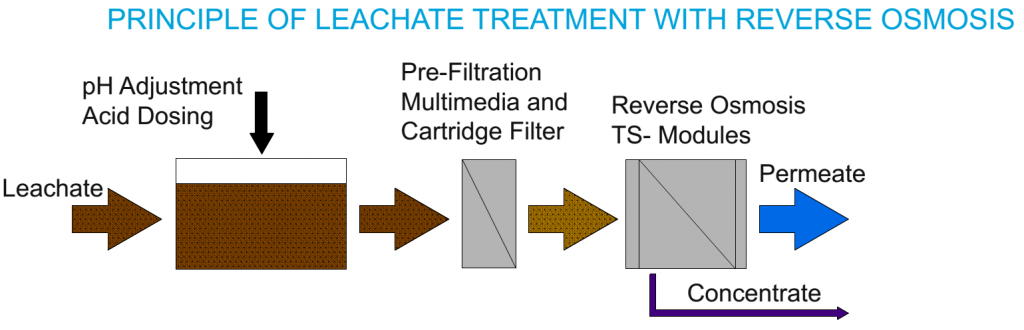

Modular design of wastewater treatment plants and RO technology play a very important role while developing solutions to abate PhACs and EDCs industrial effluents. Reverse osmosis modules as tertiary treatment after a biological treatment stage. The potential of reverse osmosis membranes to retain in their concentrate phase almost every dissolved substance (including monovalent ions), makes this technology a very suitable solution for final treatment of industrial effluents containing micro-pollutants. The main advantage of membrane technology is its wide field of application. As a technology based in a physical principle (filtration) it can be applied to separate many different substances from wastewater. Moreover, the optimal quality achieved by reverse osmosis permeate, makes this technology the keystone of every zero-discharge approach. Therefore permeate can be reused and thus contribute to reduce the overall water consumption (water footprint). |

|||||||||||||||||||||||||||||||||||||||||