| INTRODUCTION |

|

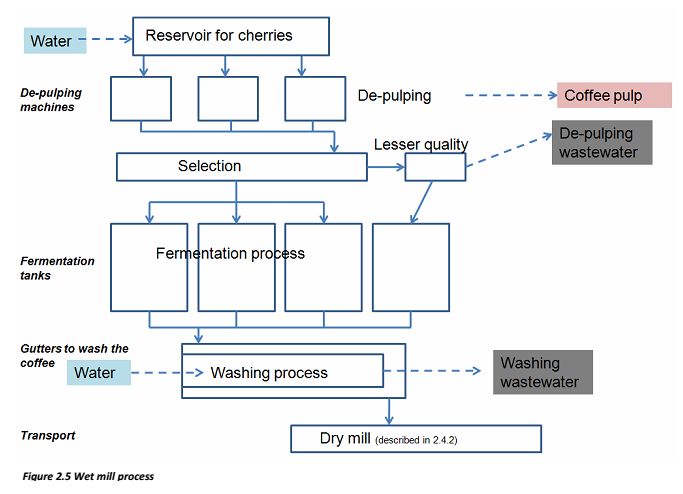

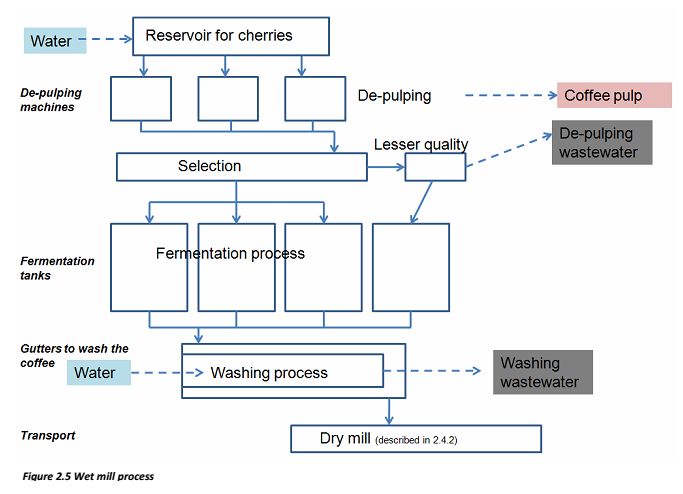

There are two different methods which can be used to process the coffee cherries: the dry mill and the wet mill. The water use at the wet mills is diverse in both quantity and purpose.

30% of the water is utilized for the de‐pulping process and 70% for the washing of the fermented grains. From this 70%, 20% is used for eliminating the decomposed mucilage and the remaining 50% is very clean wastewater that is used to finish cleaning and selecting the grains.

|

|

|

| CHARACTERIZATION OF COFFEE WASTEWATER AND RO TREATMENT PLANT |

| Coffee wastewater contains large concentrations of sugars, cellulose, caffeine and pectic substances. |

|

| Water de-pulping |

Water from washing |

| Proteines |

8.9% |

Pectic substances |

23.4% |

| Tannins |

10.0% |

Sugars |

54.2% |

| Chlorogenic acid |

14.5% |

Cellulose |

20.4% |

| Caffeine |

22.0% |

|

|

| Sugars |

45.3% |

|

|

|

|

| |

| Table 1. Characterization of coffee wastewater |

| Parameter |

Total average (mg/L) |

De‐pulping water (mg/L) |

Water from washing (mg/L) |

| Total suspended solids |

7 000 – 10 900 |

13 200 |

2 900 |

| pH |

4-5 |

4-5 |

4-5 |

| BOD5 |

10000-13000 |

1000-9000 |

1000-4000 |

| COD |

18000-23000 |

2000-14000 |

850-10000 |

|

|

The effluent from the unit was being treated in the Effluent Treatment Plant (ETP) and the discharge was being gardening towards water conservation, As corporate policy there was a requirement to reduce effluent loads through wastewater recovery for recycle/reuse.

|

| Parameters |

Unit |

Effluent (Input to RO) |

Permeate (RO Output) |

| Flow (recovery rate 66%) |

cum/day |

500 |

330 |

| pH |

- |

6.8-7.2 |

6.5 |

| Total Dissolved Solids |

ppm |

800-1000 |

100 |

| Chemical Oxygen Demand |

ppm |

220 |

10 |

| Biochemical Oxygen Demand |

ppm |

80 |

- |

| Silica |

ppm |

10 |

<1 |

| Total Suspended Solids |

ppm |

100 |

0 |

| Chlorides |

ppm |

70 |

<10 |

| Sulphates |

ppm |

<50 |

<10 |

|