How does Reverse Osmosis work ?

| |

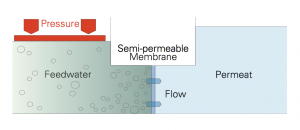

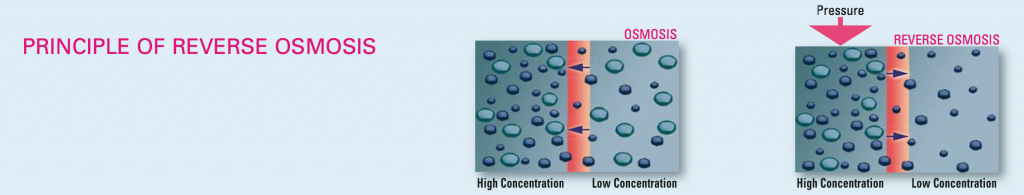

How does Reverse Osmosis work? For the production of extremely pure water, PF Membrane modules apply the reverse osmosis method. It is a reliable separation method based on a phenomenon, frequently encountered in nature, - osmosis – which describes the interaction between a weakly concentrated aqueous solution and a more highly concentrated solution which are separated by a semi-permeable membrane. The membrane is permeable to water molecules, while salts and other constituents of the water are blocked. The semi-permeable membrane permits diffusion of the water from the lower-concentration side to the higher-concentration side until an equal salt concentration is obtained on both sides (osmotic equilibrium). For reverse osmosis pressure is applied to saline water to force the pure water molecules through a semi-permeable membrane. The majority of the dissolved salts, organic material, bacteria and suspended solids are unable to physically pass through the membrane and are discharged from the system in the rejected brine. The pure water is then ready for use without further treatment.

The ROCHEM PF Module System A major advance in Reverse Osmosis Technology Rochem’s PF module technology has created major advances in the field of REVERSE OSMOSIS and its use in the desalination and purification of seawater, brackish water and city water. The PF Module is a major advance from the plate module technology which was originally developed by the West German Research Centre (GkSS). The patented PF Membrane-Module is a modern design for desalination and purification of liquids. It operates effectively and economically even at increased turbidity and Silt Density Index levels for reverse osmosis. The successful development of the PF module was only made possible by a precise technical approach in developing the total RO system. ROCHEM possesses the rare capability of being both the module manufacture and the systems manufacturer. This dual capability, plus direct contact with the end user, is of great advantage to the customer. Why is the ROCHEM PF Module System the best choice in RO? Firstly, the patented fluid dynamics and construction of the open channel, unrestricted and fully turbulent feed water flow systems means that suspended solids carried in the feed water cannot be trapped or easily settle out inside the membrane module. Most importantly, it also means that the infrequent and highly successful maintenance cleaning of the membranes can be achieved using a standard inbuilt cleaning system. Secondly, ROCHEM is committed to the use of only the highest quality of components, materials and methods of design and construction to ensure for the end user 24 hours per day reliability and product water quality. | Advantages of the ROCHEM PF Module RO System Minimizes membrane scaling and fouling. While the performance of other types of RO systems can be limited by membrane scaling and fouling, the unique fluid dynamics of the Rochem system have resolved this problem to an easily controllable degree. Simplified pre-filtration The open Channel ROCHEM RO PF module can operate without problems on filtered seawater with a Slit Density Index (SDI) as high as 15. Other systems specify SDI limits as low as 3. While simple sand filters and cartridge filters can easily achieve the SDI limits of the Rochem system the much lower limits required by other membrane systems can only be achieved by more complex filtration and chemical treatments. No chemical operating costs Unlike other RO systems the ROCHEM PF module technology does not require any permanent feed water pretreatment. High recovery rates for low energy costs Up to 30% recovery from seawater energy cost average only 10kWh/m3 of pure water. Up to 75% recovery from brackish water (TDS=5.000 ppm) – average 4kWh/m3 of pure water. Up to 85% recovery from city water (TDS=800 ppm) – average 2kWh/m3 of pure water. These figures relate to standard systems so if brine energy recovery is also employed for seawater desalination energy costs can be reduced by as much as further 50%. Long membrane life The combination of low membrane scaling and fouling, highly state membranes and a simple and effective inbuilt cleaning system means that membrane life-expectancy is normally not limited by feed water pollution in the Rochem system. Useful membrane life of 5 years or more has proved to be realistic figure. Lower membrane replacement costs Spiral wound and hollow fine fibre membrane elements are life-sealed at manufacture so the complete must be replaced at relatively high cost, but the PF Module system offers the possibility of replacing individual sheets of membrane at a fraction of the cost. High quality product water/ Latest membrane technology ROCHEM RO systems use the latest technology, chemically stable, thin film composite (tfc) membrane materials. In addition, the use of membranes in sheet form means that we can select and accurately control the quality of the installed membrane to ensure minimal salt passage to consistently produce high quality permeate. Fail-safe unattended operation The only moving part in the system is pump and all operating functions are automatically controlled and fail safe. No special skills are required to operate the system. Compact and flexible modular units The truly modular design and construction of all standard ROCHEM RO units simplifies transportation and installation and enables flexible use of limited floor space. |