Reverse Osmosis Membrane Technology

Reverse Osmosis

Outstanding expertise in reverse osmosis membrane technology

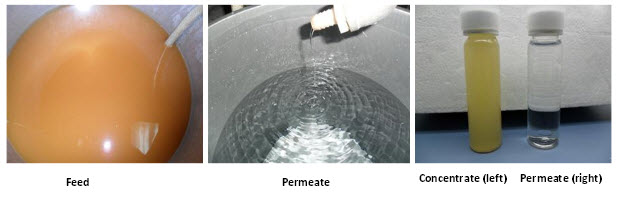

| ROCHEM has over 40 year experience in treating the most complex cocktails of industrial wastewater. Our high rejection membrane produces rejection rates of 99.8% and high water recovery rate – typically 90- 95% and also operates at high pressure up to 3.000psi. | 98,8% HIGH REJECTION RATE Using our high rejection membrane for producing high quality permeate

|

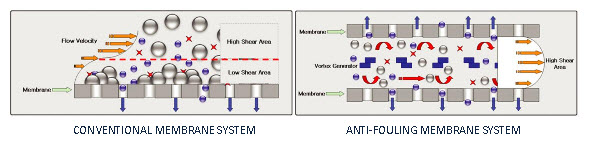

Our hydrodynamic designs, low concentration polarization and open channel design avoids fouling and scaling. Our systems are easy to clean allowing 100% performance to be recovered following cleaning. Compact standard designs reduce engineering and production costs and allows scalability.

|

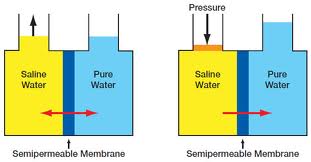

| Reverse osmosis is a reliable separation method based on osmosis, a phenomenon found in nature, where a weakly concentrated aqueous solution and a more highly concentrated solution are separated by a semi-permeable membrane. The membrane is permeable to water molecules while salt and other constituents are blocked. The semi-permeable membrane permits diffusion of the water from the lower concentrate to the higher concentrate side until an equal salt concentrate is obtained on both sides (osmotic equilibrium). |  |

|

Pressure is applied to saline water to force the pure water molecules through a semi- permeable membrane. The majority of the dissolved salts, organic material, bacteria and suspended solids are physically unable to pass through the membrane and are discharged from the system in the rejected brine. The pure water is then ready for use without further treatment.

|

Our Rochem PF Module, FM Module, Demi Water system... use advanced reverse osmosis technology and is used in the desalinization and purification of seawater, brackish water, city water, industrial waste water Recycle/ Reuse.

ROCHEM MODULE is ideal for wastewater treatment, manufacturing processes and recovery applications

Usage Field | Waster Treatment | Processing / Manufacturing | Recover/ Reuse/ Recycle |

Digestate & Livestock waste water | Anaerobic digest-ate Livestock wastewater | Biomass recovery from digestate | Nitrogen recovery for organic fertilizer |

| Chemical Processing | Cooling tower Metals removal | Colloidal suspensions Mineral salt concentration | Precious metals Methylcellulose |

Food & Beverage | Bakery wastewater Brewery wash water Winery | Juice concentration Vinegar clarification | Beer recovery Cheese whey |

| Biotech | Bio-ethenol Bio-diesel | Amino acid production Antibiotic production Herbal medicine concentration | Diafiltration for recovery |

Oil & Energy | Ion exchange brine Acid mine drainage Selenium removal | Waste oil Metal working fluids Produced water reuse | |

| Others | Landfill leachate MF backwash | Latex concentration | Paper coating effluent recovery |

Key Benefits

- No sophisticated pre-treatment

- Reliable & robust technology

- Easy to maintain

- High recovery rates with low energy costs

- Compact flexible module units

- Long membrane life

- Lower membrane replacement costs

- Wide range of standard systems

- Installed and operational in hours

- In-built cleaning& maintenance

- Reduced fouling& scaling

- Narrow and open channel design

- Chemical free filtration process

- Latest membrane technology